Why Custom iPhone 17 Cases Actually Matter (Not Just Pretty Pictures)

Your custom iPhone 17 case isn't just about showing off your latest vacation photos. It's about solving the "everyone has the same boring case" problem while keeping your $800+ investment protected. Custom doesn't mean compromised, when done right, personalized cases deliver the same drop protection as their generic counterparts.

The Real Difference Between Generic and Custom

Generic cases protect your phone. Custom cases protect your phone and tell your story. Whether you're repping your small business logo, displaying family memories, or just tired of accidentally grabbing someone else's identical black case, customization serves actual purposes beyond aesthetics.

The key difference lies in manufacturing approach. Quality custom cases use the same protective materials, air-pocket corners, raised screen edges, textured grips, but apply your design during production, not as an afterthought sticker that peels off.

Protection Meets Personality

Every worthwhile custom case starts with the same foundation: air-pocket corner technology that absorbs impact before it reaches your iPhone 17. Add the ~1mm raised screen edge and camera ring protection, and you've got drop defense that works whether your case features puppies or professional headshots.

The textured grip matters more than most realize. Custom designs printed on smooth surfaces create slippery cases that defeat the purpose. Quality options maintain that grippy-not-sticky feel that keeps your phone in your hand, not on the pavement.

Investment vs. Impulse Buy

Calculate cost-per-use over 18-24 months (typical case lifespan), and custom cases often cost less than cycling through multiple generic options. A $35 custom case used daily for two years costs roughly 5 cents per day. Plus, you actually want to keep using it instead of upgrading every few months when you get bored.

Custom cases hold resale value better and make meaningful gifts. Try explaining why someone should care about your generic clear case, then try the same with a case featuring their favorite memory or inside joke.

Understanding Your Customization Options for iPhone 17

iPhone 17 customization spans from simple photo uploads to complex multi-element designs. Each method affects both appearance and durability, so understanding your options prevents buyer's remorse and ensures your design ages well. For more insights on the latest device, check out this iphone 17 case guide.

Photo Custom Cases, From Upload to Unboxing

High-quality photo printing requires minimum 300 DPI resolution. Upload anything less, and your crystal-clear iPhone photo becomes a pixelated mess on your case. JPG and PNG files work best, avoid PDFs or low-resolution screenshots pulled from social media.

Color vibrancy depends on contrast and saturation. Images that look perfect on your bright phone screen often appear washed out when printed. Boost contrast by 15-20% before uploading, and choose photos with strong color differences rather than subtle gradients.

The mockup preview isn't just marketing, it's your last chance to catch design problems. Check how your image wraps around corners and whether important elements get cut off by camera cutouts or button placements.

Text, Monograms, and Artistic Additions

Font selection impacts both readability and durability. Thin, delicate fonts fade faster than bold, simple typefaces. Sans-serif fonts typically print clearer than serif options, especially at smaller sizes needed for phone cases.

Color contrast determines longevity. White text on dark backgrounds lasts longer than dark text on light backgrounds. High-contrast combinations resist fading better than subtle color differences that disappear as the case ages.

Strategic placement matters for wear resistance. Text near edges experiences more handling stress. Center your important text or monogram where it won't get worn down by daily grip patterns.

Material and Finish Customization

| Material | Best For | Durability | Feel |

|---|---|---|---|

| TPU | Active lifestyles | High impact absorption | Grippy, flexible |

| Polycarbonate | Minimalists | Scratch resistant | Smooth, lightweight |

| Hybrid | Best of both | Maximum protection | Textured edges |

TPU offers superior shock absorption through flexibility, it bends instead of cracking. Polycarbonate provides rigid protection in slimmer profiles. Both accept custom printing equally well, but TPU's texture affects how glossy finishes appear.

Anti-yellowing technology in clear cases prevents that gross amber tint that ruins your custom design after six months. Not all manufacturers include this, ask specifically about UV-resistant materials.

Advanced Features Compatible with Custom Cases

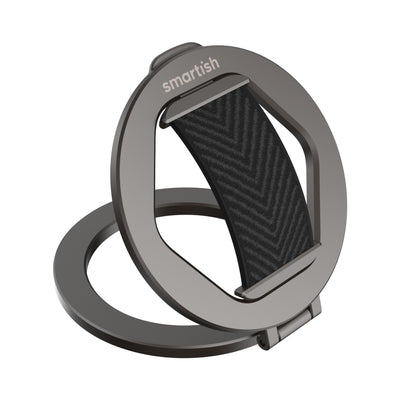

MagSafe compatibility requires precise magnet placement that custom printing can't interfere with. Quality manufacturers design around this constraint, ensuring your custom Gripmunk or Gripzilla maintains full magnetic strength.

Wallet integration adds thickness but solves the "phone plus wallet" pocket problem. Wallet Slayer Vol. 1 and Vol. 2 both accept custom designs while maintaining card security and easy access. Only Vol. 2 includes kickstand functionality.

Camera control button cutouts demand precision. Sloppy cutouts create dead zones where button presses don't register. Quality custom cases maintain exact tolerances even with complex designs surrounding the cutout area.

Protection Features That Actually Work, Not Just Marketing Hype

Real protection comes from engineering, not empty promises. The iPhone 17's premium build deserves more than cosmetic cases masquerading as protection. Understanding what actually shields your device helps you spot the difference between genuine safety features and marketing fluff. For a deep dive into rugged standards, see MIL-STD-810 testing protocols.

Air-Pocket Corner Technology, How It Works

Air-pocket corners function like crumple zones in cars, they absorb impact energy before it transfers to your phone. When your iPhone 17 hits the ground corner-first (the most common drop scenario), these engineered pockets compress and distribute force across the case structure rather than concentrating it at the impact point.

The technology requires precise manufacturing tolerances. Corners must compress enough to absorb shock but maintain structural integrity through repeated impacts. Quality implementations use reinforced TPU that rebounds to original shape, while cheaper versions crack or permanently deform after one serious drop. Look for cases that specify drop-test heights, 6-foot drops represent real-world scenarios, not laboratory fantasies.

Raised Screen and Camera Edges

That ~1mm raised lip around your screen creates a protective barrier when your phone lands face-down. The measurement matters, too little provides no protection, while excessive raising interferes with screen protectors and gesture controls. Camera rings serve the same function for your lens array, preventing direct contact with surfaces.

Custom designs must account for these raised elements during printing. Quality manufacturers ensure custom graphics don't interfere with protective geometry. The raised edges also create tactile landmarks that help you orient your phone in pockets or bags without looking.

Grip and Non-Drop Prevention

Textured surfaces prevent drops better than any amount of post-drop protection. The best custom cases maintain grip quality regardless of design complexity. Smooth, glossy prints create slippery surfaces that increase drop likelihood, defeating the purpose of protection entirely.

Ergonomic considerations matter beyond pure grip. Subtle finger grooves and rounded edges reduce hand fatigue during extended use. Your custom iPhone 17 case should feel secure in various hand positions, whether you're texting one-handed or taking photos in landscape orientation.

Design Inspiration and Personalization Ideas

Custom cases transform functional protection into personal expression. The key lies in choosing designs that reflect your personality while working harmoniously with your case's physical structure. Smart design choices create cases you'll love using for years, not months.

Photo-Based Designs That Actually Look Professional

High-contrast images translate better to case printing than subtle, low-contrast photos. Landscape photography, architectural details, and bold artwork maintain visual impact on curved surfaces. Pet portraits work exceptionally well when positioned to avoid high-wear areas along edges and corners.

Consider image orientation carefully. Vertical photos suit the natural phone orientation, while horizontal images create interesting visual tension. Multi-photo collages require careful spacing to prevent visual chaos, three focal points maximum keeps designs clean and readable.

Text-Forward Designs, Quotes, Names, Dates

Typography on curved surfaces requires larger fonts than you'd expect. Text smaller than 14-point often becomes illegible after normal wear. Monograms and single initials offer timeless appeal without readability concerns. Meaningful dates, anniversaries, achievements, milestones, create conversation starters while maintaining personal significance.

Font selection impacts both aesthetics and durability. Sans-serif fonts with thick strokes resist wear better than delicate scripts. High contrast between text and background ensures visibility in various lighting conditions.

Branded and Professional Customization

Business applications extend beyond simple logo placement. Color-coded team cases improve group coordination at events or job sites. QR codes linking to business cards or portfolios turn your case into a networking tool. Company branding on employee cases builds team identity while providing practical protection.

Professional designs benefit from restraint. Clean layouts with strategic white space appear more sophisticated than busy, element-heavy designs. Consider your industry's visual expectations, creative fields allow more experimental approaches than traditional corporate environments. For more inspiration, read this best iphone 17 pro max case roundup.

Custom Case Care, Maintenance, and Longevity

Protecting your investment requires understanding how custom elements respond to daily use and environmental factors. Proper maintenance extends both protection performance and visual appeal, keeping your personalized design looking fresh throughout your iPhone 17's lifespan.

Cleaning Without Fading, The Right Way

Gentle cleaning preserves custom prints while removing accumulated grime. Use lukewarm water with mild soap, harsh chemicals break down printing inks and case materials. Microfiber cloths clean effectively without scratching printed surfaces. Avoid paper towels or rough fabrics that create micro-abrasions over time.

Weekly cleaning prevents buildup that requires aggressive scrubbing. Focus on high-touch areas like button covers and grip zones where oils and dirt concentrate. Thorough drying prevents moisture from seeping under printed elements, which can cause lifting or discoloration.

Preventing Print Fading and Discoloration

UV exposure gradually breaks down printing inks, causing colors to shift or fade. While complete sun avoidance isn't practical, limiting prolonged direct sunlight exposure helps preserve vibrancy. Car dashboards and sunny windowsills create particularly harsh UV conditions. For more on electronics safety, see this Smartphones and Electronics safety guide.

Quality printing processes use UV-resistant inks that maintain color stability for 2-3+ years under normal use. Clear cases with custom elements may show slight yellowing over time, this represents normal material aging rather than defective manufacturing.

Addressing Wear Spots and Minor Damage

Corners and edges experience the most stress during daily use. Minor scuffing in these areas indicates your case is doing its job, absorbing impacts that would otherwise damage your phone. Significant cracking or structural damage requires replacement for continued protection.

Print wear typically appears gradually around high-friction zones. Strategic design placement during customization minimizes visible wear by avoiding these predictable stress points.

Troubleshooting Common Custom Case Issues

Even well-designed custom iPhone 17 cases can present challenges. Here's how to identify and resolve the most frequent problems before they impact your phone's protection. For additional troubleshooting tips, you might also find this best iphone 17 protective case article helpful.

Fit Issues, Too Tight, Too Loose, or Port Misalignment

Poor case fit stems from three primary causes: manufacturing tolerance variations, incorrect model selection, or design interference with structural elements. Early warning signs include difficulty removing your phone, blocked port access, or cases that slide around during use.

Measure your iPhone 17's exact dimensions if fit seems questionable. Standard iPhone 17 measures 5.81" × 2.82" × 0.31", while the Pro Max reaches 6.33" × 3.06" × 0.32". Even small variances affect case performance.

Best for: Anyone experiencing installation difficulties or accessory compatibility issues.

Port misalignment typically indicates wrong model selection during ordering. Camera control button cutouts require precision, if your custom case blocks this feature, contact support immediately for replacement.

Design-to-Print Accuracy Gaps

Color matching between screen mockups and physical prints varies due to display calibration differences. Professional monitors show colors differently than phone screens, creating expectation gaps.

Resolution loss during printing becomes visible when source images fall below 300 DPI. Your custom iPhone 17 case design should use images at least 1500×3000 pixels for optimal clarity. Placement discrepancies of 1-2mm fall within acceptable industry tolerance.

Return eligibility applies when color variance exceeds 15% from mockup or when resolution appears pixelated despite meeting file requirements. Document issues with photos for faster resolution processing.

Material and Build Quality Concerns

Case cracking typically occurs at stress points, corners and port openings. TPU cases flex during impact, while polycarbonate maintains rigidity. Neither should crack under normal use within the first year.

Print bubbling or peeling indicates application temperature issues during manufacturing, not design problems. This qualifies as a manufacturing defect requiring replacement.

Material defects present as inconsistent texture, unusual odors, or structural weakness in areas that shouldn't flex. Document these issues immediately, most manufacturers honor defect claims within 30-90 days.

Wireless Charging and Accessory Compatibility

Case thickness impacts MagSafe alignment more than material composition. Cases exceeding 3mm thickness may require precise phone placement for consistent charging.

Metal design elements interfere with wireless charging regardless of case quality. Avoid metallic inks or embedded metal decorations if wireless charging matters to your daily routine.

Wallet cases create inherent MagSafe conflicts, the wallet blocks magnetic attachment for other accessories. Choose wallet functionality OR MagSafe compatibility, not both simultaneously.

Kickstand mechanisms can interfere with charging plates depending on orientation. Test your setup before relying on this combination for daily use.

Customization Options Comparison, Which Features Matter Most

Understanding feature trade-offs helps prioritize what matters for your specific needs. Not every customization option delivers equal value. For a broader look at iPhone 17 features, see this iphone 17 overview.

Slim vs. Protective Custom Cases, Trade-offs

Drop protection differs measurably between slim and protective designs. Slim cases handle 4-foot drops effectively, while protective cases manage 6+ foot impacts thanks to thicker corner reinforcement.

Bulk measurements matter for pocket compatibility. Slim custom cases add 1-2mm total thickness, while protective options add 3-4mm. This difference affects wireless charging pad alignment and car mount fit.

Best for slim: Professionals prioritizing aesthetics and minimal bulk who handle phones carefully.

Best for protective: Active lifestyles, parents, or anyone prone to drops who needs maximum impact protection.

Both styles maintain textured grip surfaces and precise port cutouts. Air-pocket corners appear in both categories, protective cases simply use larger air chambers.

Photo-Heavy vs. Minimalist Design Approaches

Complex multi-image designs lose clarity when printed on curved surfaces. Images with fine details become muddy around case edges where material curves.

Minimalist designs age better visually. Simple monograms or single-color backgrounds maintain crisp appearance longer than busy patterns that show wear inconsistently.

Best for photo-heavy: Memory preservation, gift-giving, or personal expression where visual impact trumps longevity concerns.

Best for minimalist: Professional environments, users who change cases frequently, or those prioritizing timeless aesthetics.

Maintenance ease favors simpler designs. Fewer visual elements mean wear patterns blend better with overall appearance.

Clear Cases vs. Full-Print Coverage

Clear custom iPhone 17 cases showcase your phone's original design while adding personalized elements. Anti-yellowing technology maintains clarity for 18+ months with proper care.

Full-print coverage protects underlying case material from UV exposure and wear, potentially extending case lifespan. Print layers act as protective barriers against scratches.

| Feature | Clear Cases | Full-Print Cases |

|---|---|---|

| Design flexibility | Limited to edges/corners | Complete surface coverage |

| iPhone visibility | Shows original design | Completely covered |

| Discoloration visibility | Highly visible yellowing | Hidden by print layer |

| Print longevity | Good with UV-resistant ink | Excellent, print layer protects |

Frequently Asked Questions

How do custom iPhone 17 cases provide the same level of protection as generic cases?

Quality custom iPhone 17 cases use the same protective features as generic ones, like air-pocket corners and raised edges around the screen and camera. These elements absorb impact and keep your phone safe without compromising on your unique design.

What are the best file types and image quality requirements for photo customizations on iPhone 17 cases?

For crisp, clear photo customizations, use JPG or PNG files with a minimum resolution of 300 DPI. Lower-quality images can appear pixelated and reduce the overall look of your case.

Why is textured grip important in custom iPhone 17 cases, and how does it affect usability?

Textured grip keeps your phone secure in your hand, preventing slips and drops. Custom cases printed on smooth surfaces can be slippery, so maintaining a grippy, not sticky, texture is key for everyday usability.

How can I ensure that text and monograms on my custom case remain readable and durable over time?

Choose bold, simple fonts and high-contrast colors to keep text clear. Also, opt for cases where designs are printed during production, not applied as stickers, to ensure durability and prevent fading or peeling.